Airbus, AMS, Boeing, Bell Helicopter, Cessna, Douglas, Military, Spirit Aerosystems & Triumph Vought, Including D1-4426 approvals for AMS, BAC, DPS & MIL specs.

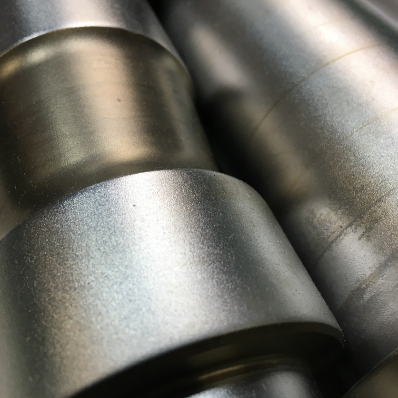

Hytek offers precision hard chrome plating services engineered for the aerospace sector. This gray-white, high-luster finish provides excellent resistance to wear, heat, and corrosion, making it ideal for components subjected to high mechanical loads or sliding contact. The process supports high-thickness builds, restoring dimensional tolerances on worn or machined parts. We partner with a local grind shop to deliver close-tolerance finishes, and our in-house capabilities focus on precision aerospace plating to minimize downstream grinding, reduce lead time, and support tight engineering specifications for critical applications.

Common Applications Include:

Specification Approvals:

AMS2460, BAC5709, CSF029, DPS9.71, DPS9.84, SOPM20-42-03, D1-4426 approvals for AMS, BAC, DPS & MIL specs.

Hytek also provides Thin-Dense Chrome—a microcracked, low-thickness, very hard chrome deposit designed for enhanced wear resistance, low coefficient of friction, and uniform coverage without significant dimensional buildup. This variation is ideal for aerospace tooling, bushings, and small-diameter internal features where precision and smooth operation are paramount. It offers superior adhesion and fatigue resistance, making it especially valuable for applications requiring both hardness and exact dimensional control as required in aerospace plating.

Common Applications Include:

Specification Approvals:

AMS2460, BAC5709, CSF029, DPS9.71, DPS9.84, SOPM20-42-03, D1-4426 approvals for AMS, BAC, DPS & MIL specs.

For applications requiring reduced reflectivity and glare, Hytek offers Satin or Matte Chrome finishes. These coatings deliver the same corrosion and wear resistance properties of standard chrome plating but with a diffused, low-gloss appearance. Often used in cockpit hardware, control interfaces, or external surfaces exposed to light-sensitive environments, satin chrome combines functionality with aesthetics while maintaining aerospace-grade performance. It’s attractive satin finish is very repeatable allowing for differant alloys to be plated and all look the same.

Common Applications Include:

Specification Approvals:

AMS2460, BAC5709, CSF029, DPS9.71, DPS9.84, SOPM20-42-03, D1-4426 approvals for AMS, BAC, DPS & MIL specs.

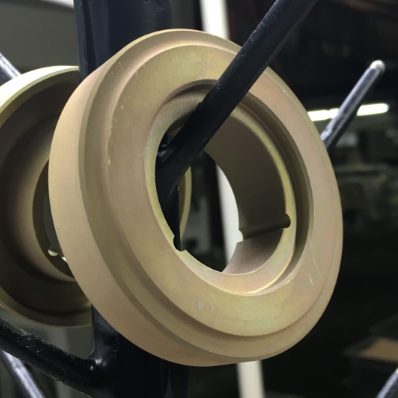

Cadmium plating by Hytek delivers essential sacrificial corrosion protection for aerospace assemblies, particularly in salt-heavy or galvanically aggressive environments. This coating is especially suited for components that interface with aluminum or brass, helping to prevent galvanic corrosion. Our cadmium plating process meets rigorous OEM standards, including AMS-QQ-P-416 & D1-4426, providing excellent lubricity, solderability, and EMI shielding. It is a go-to finish for fasteners, connectors, and aerospace structural hardware exposed to harsh environmental conditions.

Common Applications Include:

Specification Approvals:

AMS-QQ-P-416, BAC 5701, BAC 5734, BAC 5849, BAC 5854, BPS 4312, BPS 4006, BPS 4312, DPS 9.28, DPS 9.74, Mil-STD-865, QQ-P-416, SOPM 20-42-05, SOPM 20-42-10, D1-4426 approvals for AMS, BAC, & DPS specs.

Ti-Cad (Titanium-Cadmium also known as Cadmium-Titanium) plating is a high-performance aerospace coating designed specifically for high-strength steels exceeding 220 KSI. Titanium-Cadmium plating is an advanced surface treatment significantly enhancing corrosion resistance—offering superior protection compared to conventional cadmium plating—and is engineered to mitigate the risk of Hydrogen Embrittlement, which is critical for maintaining the integrity of load-bearing components. Hytek’s Ti-Cad process is tightly controlled to meet stringent aerospace and OEM specifications and is ideally suited for structural fasteners, landing gear hardware, and engine support assemblies where maximum durability, conductivity, and environmental resistance are essential.

Common Applications Include:

Specification Approvals:

AMS 2419, BAC 5804, BAC 5854, MIL-STD-1500, SOPM 20-42-02, D1-4426 approvals for BAC specs.

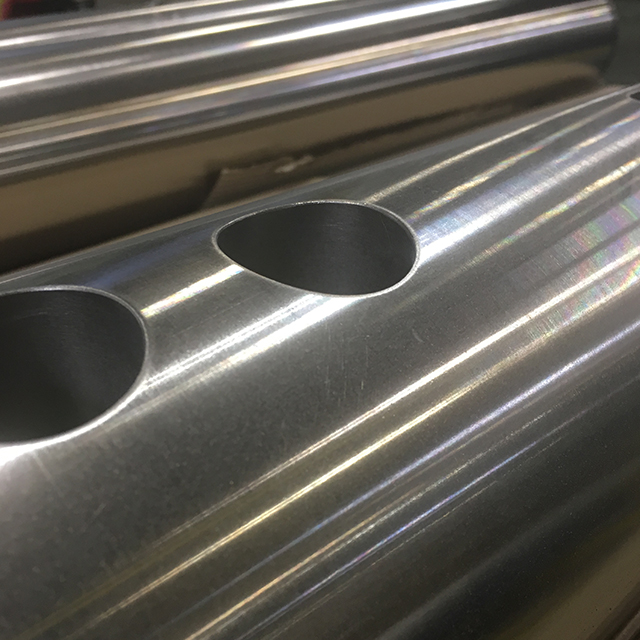

Zinc-Nickel plating is a high-performance, environmentally compliant alternative to cadmium plating, offering superior corrosion resistance and exceptional durability in aerospace environments. Hytek’s alkaline Zinc-Nickel process provides excellent adhesion and uniform deposition on both internal and external surfaces, supported by dedicated tanks for ID/OD (inner/outer diameter) plating. With a deposit composition typically around 12–15% nickel, this finish is engineered to mitigate galvanic corrosion on high-strength steel components mated with aluminum, making it an ideal choice for airframes, landing gear hardware, and hydraulic fittings. The process meets stringent AMS and OEM specifications, delivering long-term protection in mission-critical applications.

Common Applications Include:

Specification Approvals:

AIPS02-04-006, AMS 2417, BAC 5637, BAC 5680, CPS 8203, D1-4426 approvals for AMS & BAC specs.

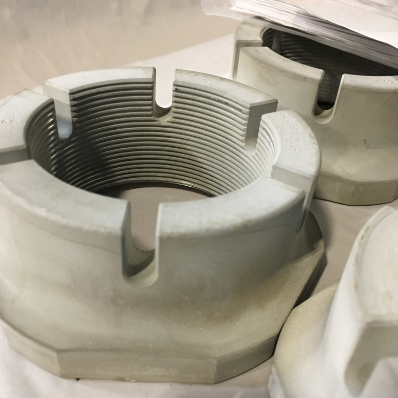

Hytek’s electroless nickel plating process utilizes an acid-based, autocatalytic deposition method that ensures uniform thickness and excellent coverage—even on complex geometries, recesses, and small-diameter bores. This coating offers high hardness, wear resistance, and outstanding corrosion protection without the need for electrical current, making it more consistent and predictable than electrolytic alternatives. Electroless nickel is particularly effective at preventing galling, fretting, and surface degradation under mechanical stress. Suitable for both steel and aluminum substrates, it is widely used in aerospace for bushings, valve components, tooling, and intricate assemblies where dimensional precision and surface performance are critical.

Common Applications Include:

Specification Approvals:

AMS 2404, AMS-C-26074, BAC5728,MIL-C-26074, D1-4426 approvals for AMS, BAC & MIL specs.