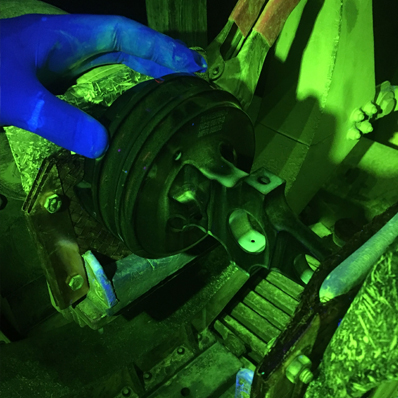

Magnetic Particle Inspection is a very sensitive method of inspecting and locating surface or near surface defects in ferromagnetic materials. Magnetic particles are applied to the surface in a liquid suspension. The particles reveal the location, size, shape and extent of the defects.

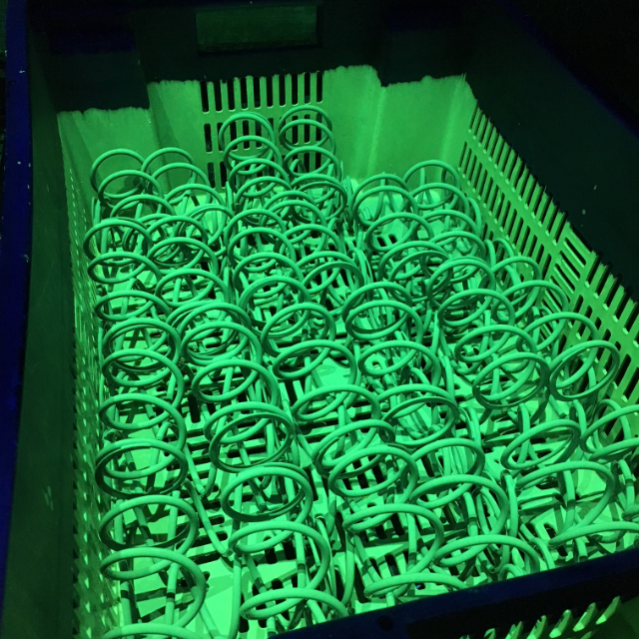

Penetrant Inspection is a method of inspection for the surface of metals and other nonporous solids for cracks, pits and other defects. The process utilizes fluorescent, water-washable liquid that is allowed to enter defects that can then be identified under black light.

This chemical process reveals grinding and machining burns, decarburization, rehardening, retempering or case leakage.