Specification Approvals:

Airbus, ASTM, Bell Helicopter, Blue Origin, Boeing, Bombardier, Cessna, Douglas, Goodrich Aerostructures, Israeli Air, Pratt & Whitney, Military, Safran, Sikorsky, SpaceX, Spirit Aerosystems & Viking, Including D1-4426 approvals for AMS, ASTM, BAC, BSS DPS & MIL specs.

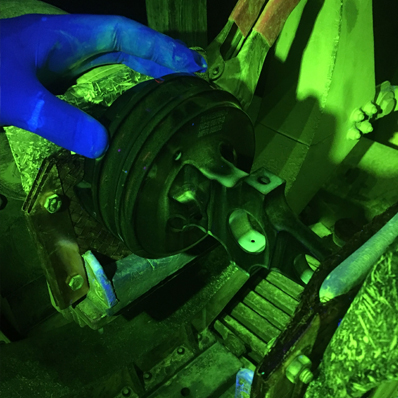

Magnetic Particle Inspection is ideal for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as steel, iron, and certain nickel alloys. The part is magnetized either directly or indirectly, and then a suspension of magnetic particles is applied. Defects at or near the surface cause distortions in the magnetic field, attracting the particles and forming visible indications. High frequent processing for BAC 5424 & ASTM-E-1444.

Applications:

Process Highlights:

Specification Approvals:

ASTM-E-1444/E1444M, BAC 5424, BAPS 176-004, CPC 9108, CSTI001, DPS 4.704, PCS-3100, PS 21201, RPS 18.08, SOPM 20-20-01, SPS-104240, 8-SS805, VPS 20.01

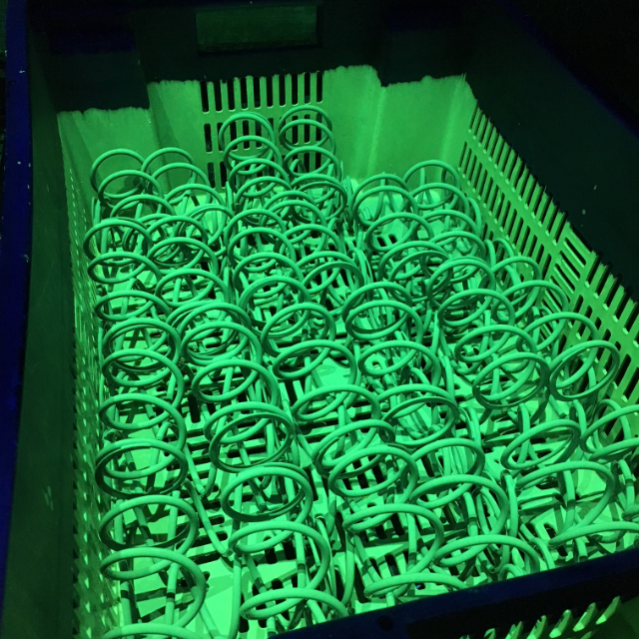

Penetrant Inspection is a widely used method for detecting discontinuities on nonporous metal surfaces, such as aluminum, titanium, and stainless steel. A fluorescent dye penetrant is applied and allowed to seep into surface-breaking defects. Excess penetrant is removed, and a developer is applied, drawing the penetrant out of flaws to form visible indications under ultraviolet (black) light. High frequent processing for BAC 5423, ASTM-E-1417 & AITM6-1001.

Applications:

Process Highlights:

Specification Approvals:

208-14-13, ABP6-5230, AITM6-1001, ASTM-E-1417/E1417M, BAC 5423, BPS 4089, CTI002, DPS 4.707, FPM-CODE2, PCS-3200, PS 2030, PS 21202, RPS 18.10, SOPM 20-20-02, SPS-104230, 8-SS8806, VPS 20.03

Nital Etch is a chemical inspection process used to detect heat-induced surface damage that causes microstructural changes in hardened steels. It exposes anomalies like overheating (grinding burns), decarburization, case leakage, and other thermal effects that are often invisible to the naked eye. The process uses a solution of nitric acid to etch the part surface, revealing contrast variations where issues are present. High frequent processing for BAC 5436 & MIL-STD-867.

Applications:

Process Highlights:

Specification Approvals:

BAC 5436, DPS 4.715, MIL-STD-867, SOPM 20-10-02